Flexible screw conveyor

Flexible auger conveyors are capable of conveying a wide range of dry bulk solids (free flowing powders, granules, small pellets) in any direction

Flexible auger conveyors are capable of conveying a wide range of dry bulk solids (free flowing powders, granules, small pellets) in any direction

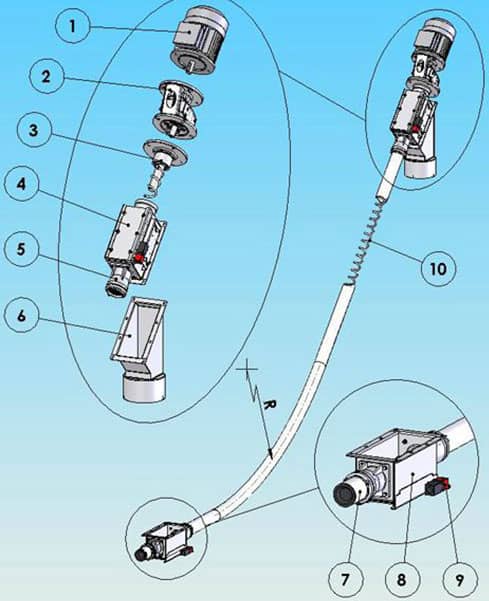

Dust protection

Protection against product inflitration by static and dynamic seal rings

Easy cleaning

By gates located at the pick up and unloading positions of the conveyor

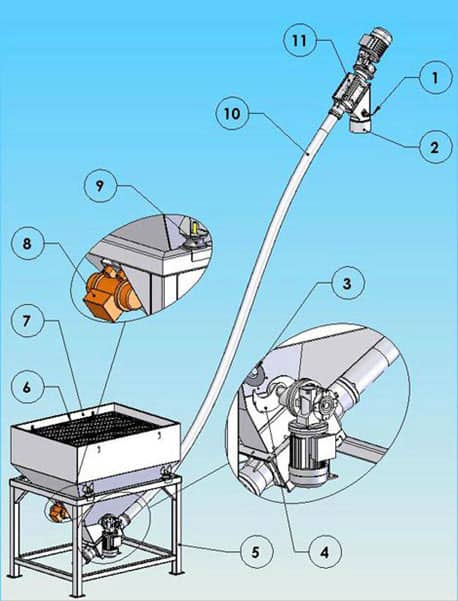

This type of powder transfer systems easily fits to existing plants thanks to its flexibility to overcome significant differences in height and cover long distances. The rotary spiral is made of carbon or stainless steel thermally treated in round, rectangluar or squared sections, depending on the application required. The spiral drive shaft is supported by means of roller bearing inserted in the flanged body of connection with the electric motor: in this way the motor bearing are not affected by the stresses transmitted by the spiral.

Our flexible screw conveyors can easily integrate with a complete range of upstream and downstream powder handling equipment, also with portable base frame with wheels.

You can find an example of a multiple flexible screw conveyor system for material handling in food processing, from bulk bag unload to weighing hoppers, complete with vibrating screen and agitator.

ATEX - Explosion Proof Protected

All Gimat flexible spiral conveyors are available ATEX rated for use in explosive atmospheres (Directive ATEX 2014/34/EU FOR ZONE 2-22 / ZONE 1-21).

Despite its conceptual simplicity, this powder conveying system requires custom engineering for each case by our technical department to meet specific customer needs, offering key benefits in powder conveying, such as:

Homogenize products during transport

Prevent demixing of already mixed/batched bulk materials

Silent running operation

Portable versions on wheels with hoppers

In the same product line see also:

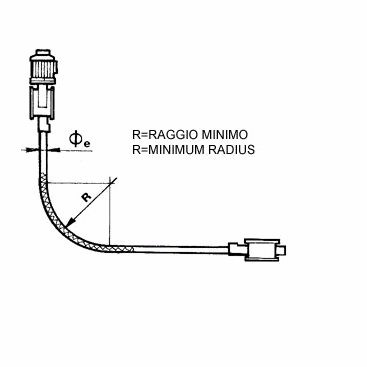

Pneumatic conveyor| Model | Capacity (litres/h) | Outside diameter (mm) | Minimum bending radius (mm) |

|---|---|---|---|

| MAR 55 | 400 | 55 | 1400 |

| MAR 65 | 850 | 65 | 1600 |

| MAR 70 | 1250 | 70 | 1800 |

| MAR 80 | 1800 | 80 | 2500 |

| MAR 90 | 2500 | 90 | 2800 |

| MAR 100 | 3500 | 100 | 3000 |

| MAR 110 | 4600 | 110 | 3800 |

| MAR 125 | 7500 | 125 | 4500 |

The flow rate calculations were made based on these assumptions: