bulk bag filler

Gimat big bag filler is an efficient and easy to use unit designed for bagging large quantities of bulk materials

Gimat big bag filler is an efficient and easy to use unit designed for bagging large quantities of bulk materials

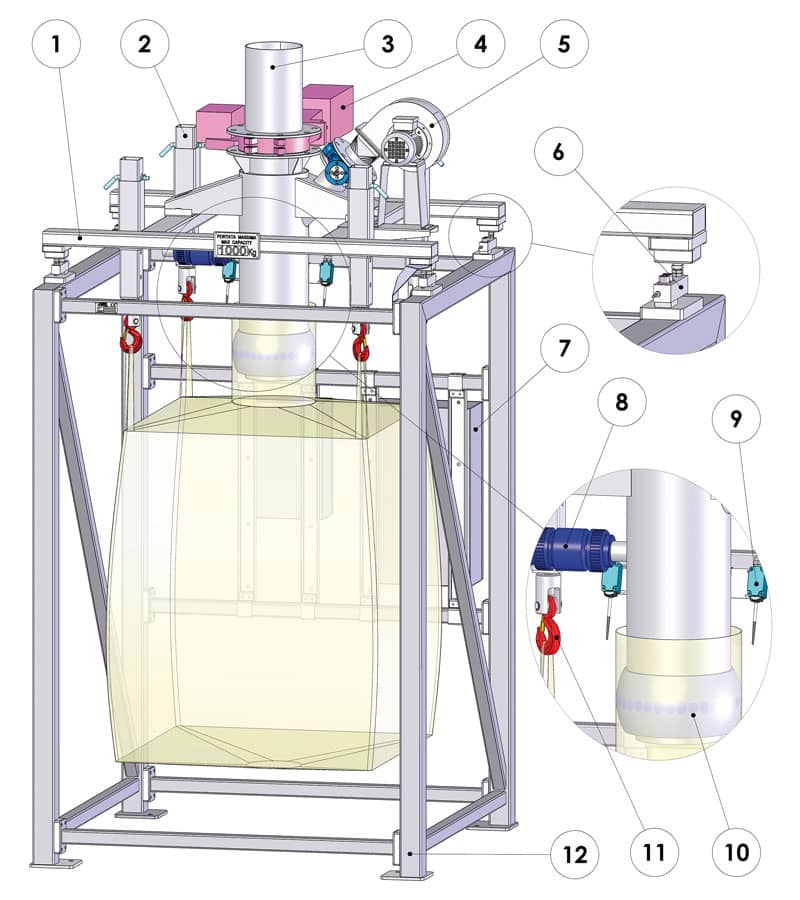

Telescopic frame

Adjust the height to the dimensions of bulk bag, with optional pneumatic pistons

Load cells

For accurate weighing (complete with anti-tipping device)

Inflatable pneumatic neck seal

For a dust-free air displacement during filling

We produce 2 standard models for filling FIBCS, designed for bag capacities of 2,200 lb (1000kg) and 4,400 lb (2000 kg). Gimat bulk bag filler unit is dust free and benefits from an adjustable frame (made of stainless steel Aisi 304 or 316) to accommodate a wide range of different bag heights. Thanks to its modular design our bulk bag loader can be easily combined and integrated in any powder processing and packaging applications. The filled bulk bag can be easily removed by forklift or pallet jack.

ATEX - Explosion Proof Protected

On request the bulk bag filling station can be designed and manufactured in compliance with the Directive ATEX 2014/34/EU FOR ZONE 2-22 / ZONE 1-21

Specially designed filling head

A rubber sleeve with pneumatic inflation ensures a tight connection to effectively contain the dust during the bulk bag filling operations.

Bulk bag inflation

By electric fan or pneumatic air blower, to fully expand the bag and maximize fill volume.

Vibrating table/ Pneumatic pistons

The special Gimat configurations of the big bag filling frame, designed to improve the filling coefficient, depending on the type of material.

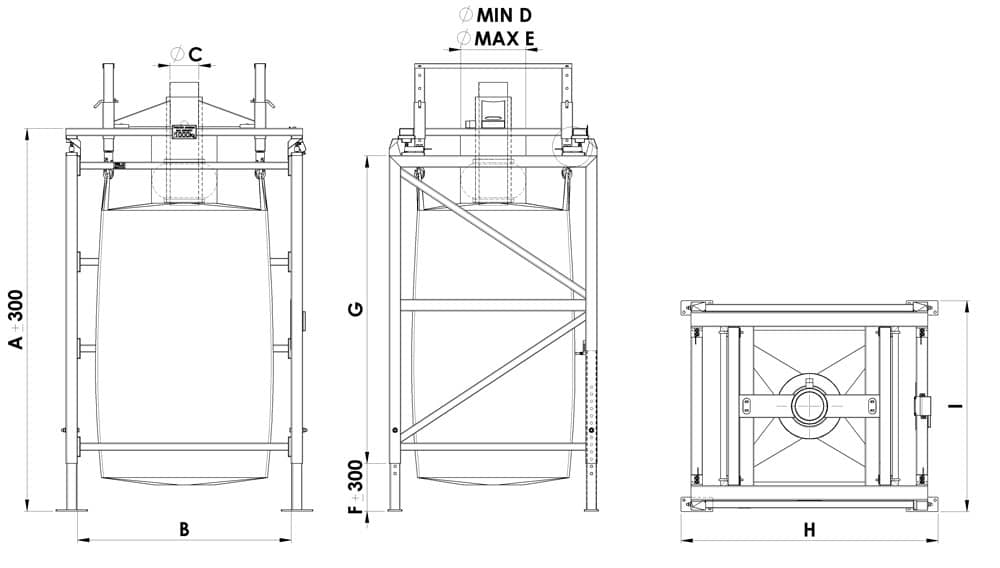

| Model | Max Load (kg) | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | H (mm) | I (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| SSR.10/20 | 1000/2000 | 2900 | 1480 | 200 | 282 | 500 | 330 | 2130 | 1780 | 1460 |

Mobile structures on request: we can realize bulk bag filling frames with height-adjustable wheels, enabling easy relocation within the production area.

Handling abrasive and/or very hot materials in industrial processes presents some challenges when filling big bags, such as safety risks, wear and tear of equipment, material flow issues, bag integrity and bagging speed and efficiency.

In this station, complete with a weighing system, the material is conveyed by a tubular conveyor in stainless steel and flexible spiral. The 2-way electro-pneumatic diverter can quickly switch from one bulk bag filler to another, without interrupting the production cycle.

When considering a new big bag filling system, the primary gol is to reduce operational and labor costs while optimizing the bag fill rate, which is usually measured by how many bags can be filled per hour.

Fill rates can be adjusted, varying between a slow stream and a steady flow (for safety reasons, as well as for efficiency). The rate at which bulk bags are filled is influenced by several factors, such as material properties, infeed source and the facility conditions; for this reason, it is essential that the bulk bag filler is suitably equipped with the correct features to suit the application and to be easily moved within the production facility.

To achieve a seamless process, pay close attention to the details in each of the three phases.

Preparing the bulk bag

Before proper filling, hang and position the big bag correctly to allow the side-walls to stretch properly. This step is crucial to ensure the bags remain stable and upright after filling.

Filling the bulk bag

The big bag spout is securely placed over the fill head to ensure a tight, dust-free seal. The bulk bag or liner may then be inflated with air. It is at this stage that densification strategies should be applied, using a vibratory deaeration/densification deck, for example.

Bulk bag removal after filling

The fill rate can be further optimized through the efficient removal of filled big bags, using chain conveyors or slip sheet dispensers.

To achieve an accurate and consistent filling process, a metered feeding system is required. This can involve a flexible screw conveyor, a rotary valve or another device that ensures material delivery without solely depending on gravity.