Gimat’s powder transfer systems

Powder conveying systems for bulk material handling are an integral component of various industrial processes, particularly in sectors like pharmaceuticals, food and beverages, chemicals, and construction. These systems are designed to move large quantities of powdered or granular materials safely, efficiently, and hygienically from one location to another.

The choice of system depends on a variety of factors. As technology advances, these systems are becoming more sophisticated, offering higher efficiency, better integration, and smarter operation. For industries reliant on bulk material handling, investing in the right powder transfer system can lead to significant improvements in productivity, safety, and quality.

Technological advantages of Gimat solutions

Automation

Integration with automated controls for precise and efficient operation.

Smart Monitoring

Sensors and IoT devices to monitor system performance and predict maintenance requirements.

Eco-friendly Designs

Systems designed to reduce energy consumption and minimize waste.

Safety

User-friendly interface, environmental dust containment, optimized manual bag handling.

Pneumatic Conveying Systems

We design and create powder transfer systems mostly using vacuum pumps in both dilute (lean) phase and dense phase. Dense phase is chosen in case of abrasive, fragile materials or to reduce de-mixing issues.

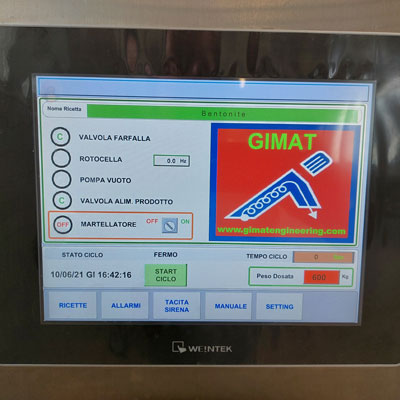

Here we show you a small efficient system for pneumatic conveying and powder dosing for the wine industry. Dilute phase pneumatic vacuum conveyor of bentonite powder and granules into a dissolving tank. The sack tip station is equipped with a dust hood containment and centralized suction. The powder transfer system (MOCA 1935/2004 certified) has a cyclone-filter with a teflon-coated sleeve filters with counter-current air cleaning. Stainless steel rotary valve "easy cleaning" version, with easily removable rotor for cleaning.

Equipment

Mechanical powder conveying systems

We design and produce a wide range of mechanical conveyors. In the systems designed by Gimat, we can integrate flexible screw conveyors, shaftless, tubular and U-trough screw conveyors, according to the application.

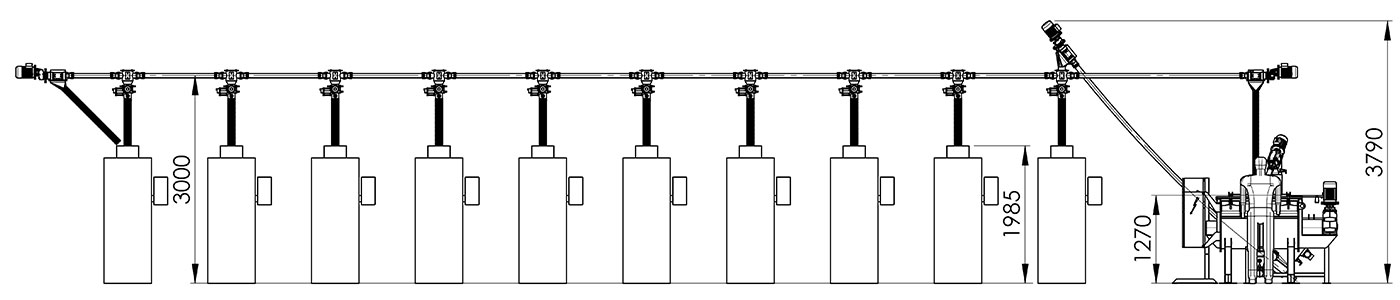

This is a comprehensive powder conveying system for producing corn and rice cakes. The system features bulk bag unloading, rice and corn transfer and dosing through dedicated easy-cleaning flexible screw conveyors. A gravimetric feeder is used for accurate salt dosing. Horizontal ribbon mixer homogenously mixes all components tougher with a controlled water addition. Multiple feeding, without de-mixing, of the puffing machines thank to a single high capacity horizontal flexible screw conveyor.

Equipment

Factors to consider when choosing a powder transfer system

Material Characteristics: the nature of the material (e.g., size, abrasiveness, moisture content) will affect the choice of system.

System Design: correct design is crucial to ensure minimal wear and tear, avoid blockages, and maintain energy efficiency.

Regulatory Compliance: systems must adhere to industry standards and regulations, particularly in pharmaceutical and food industries.