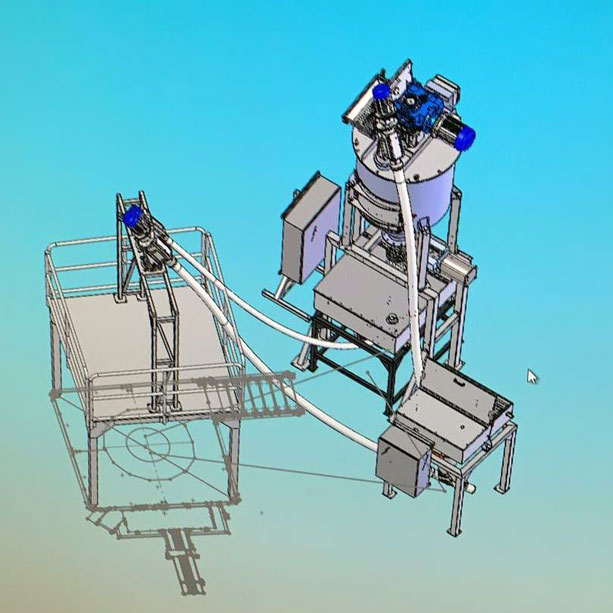

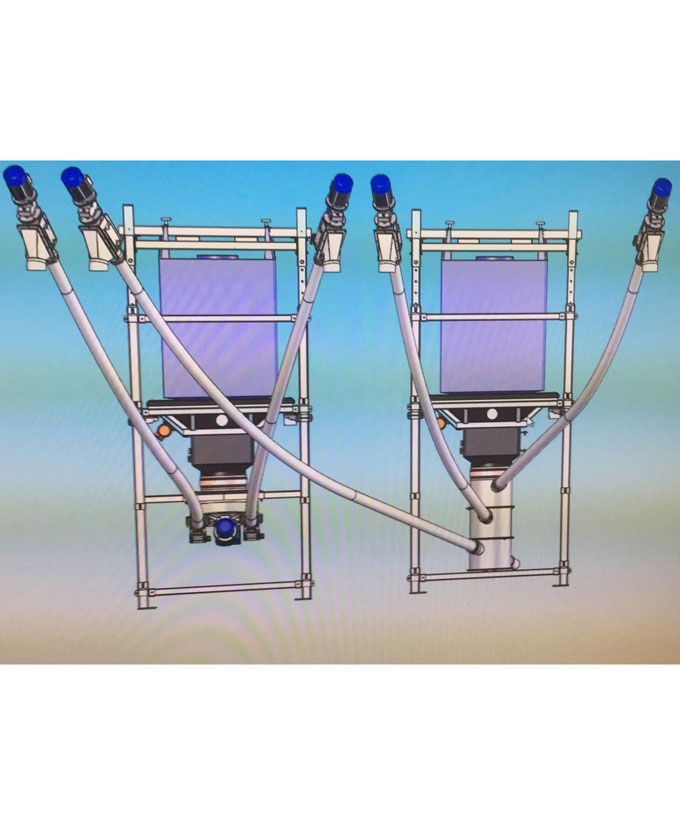

Twin High-Capacity Bulk Bag Unloader and conveying of recycled silica sand to a texturing blender

Customer requirement: This major UK manufacturer of concrete building products had a specific requirement to quickly feed recycled and virgin silica sand to a new texturing mixer within a pre-determined timeframe.

Due to the volume of raw materials that was required for the process it was impossible that a single operator would be able to load and unload the FIBC bulk bag discharging equipment within the required timeframe to keep up with the production requirement of the mixing process. The addition of a new texturing mixer was part of a much larger project to increase production in their range of textured bricks. The ability to recycle silica sand which is collected during their existing manufacturing processes and re-filled into Flexible Bulk Bags within the company was an important part of the sustainability and waste reduction policy.

- The customer demands were to transfer a specific amount of recycled raw materials from the bulk bags and virgin silica sand from a new bulk silo within a few minutes.

- The process would have to be completed by a single multi-skilled operator and the equipment had to integrate within a larger SOP (standard operating procedure) and programmable control system supplied by the automation provider.

- The bulk bag discharging equipment had to run at an optimum speed range to ensure energy efficiency during operation.